We offer revolution of industrial engineering

Mflow Engineering & Services Sdn Bhd

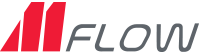

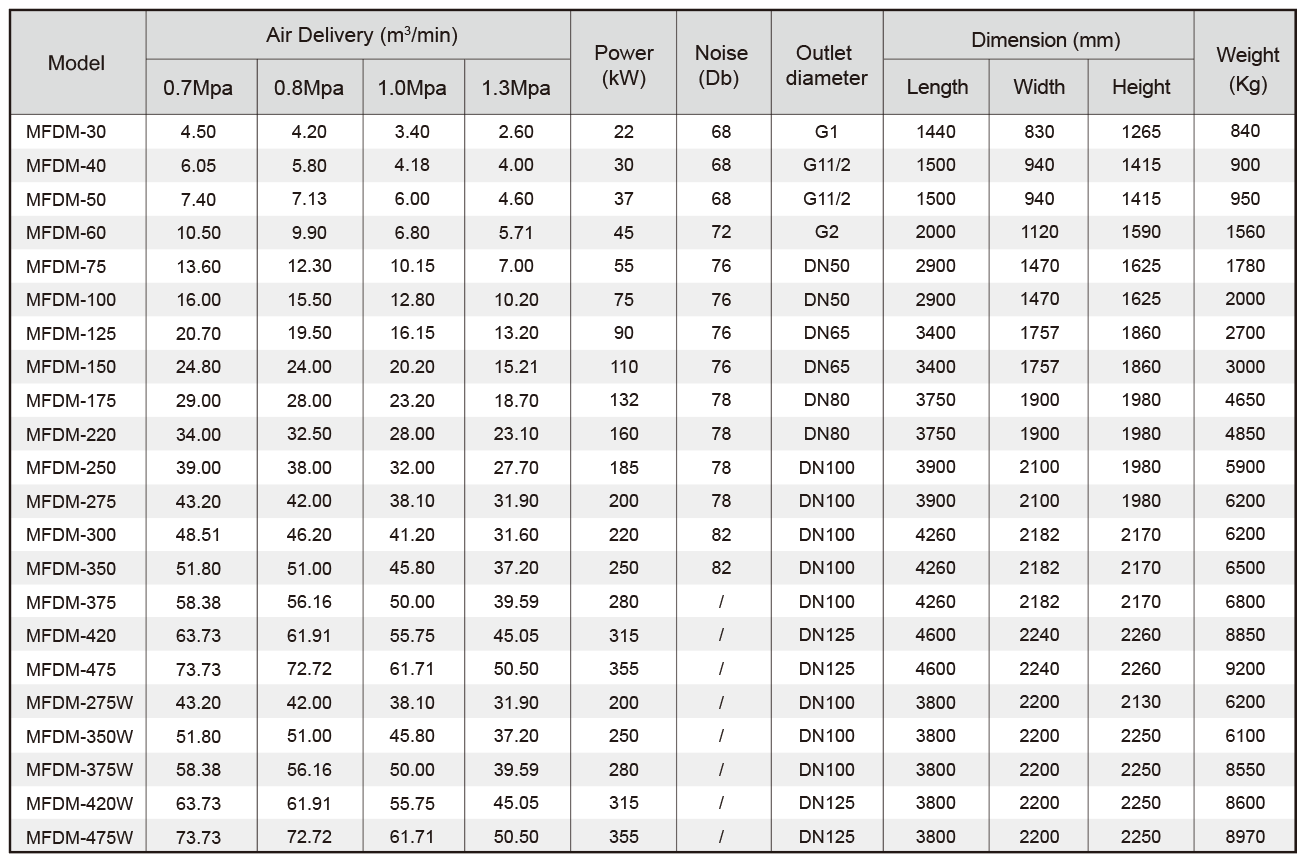

Intelligent Pm Vsd Screw Air Compressor

- IE3 high-efficiency energy-saving PM motor saves energy up to 6-7%, compared with three phase asynchronous motor.

- Latest air end, one-shaft structure,more compact, stable, Level 1 national standard of energy efficiency.

- Due to intelligent inverter technology, PM VSD air compressor saves energy up to 42%.

- Internet remote control technical – your compressor-keeper.

- MFLow proprietary technologies.

Specification

Mflow Engineering & Services Sdn Bhd

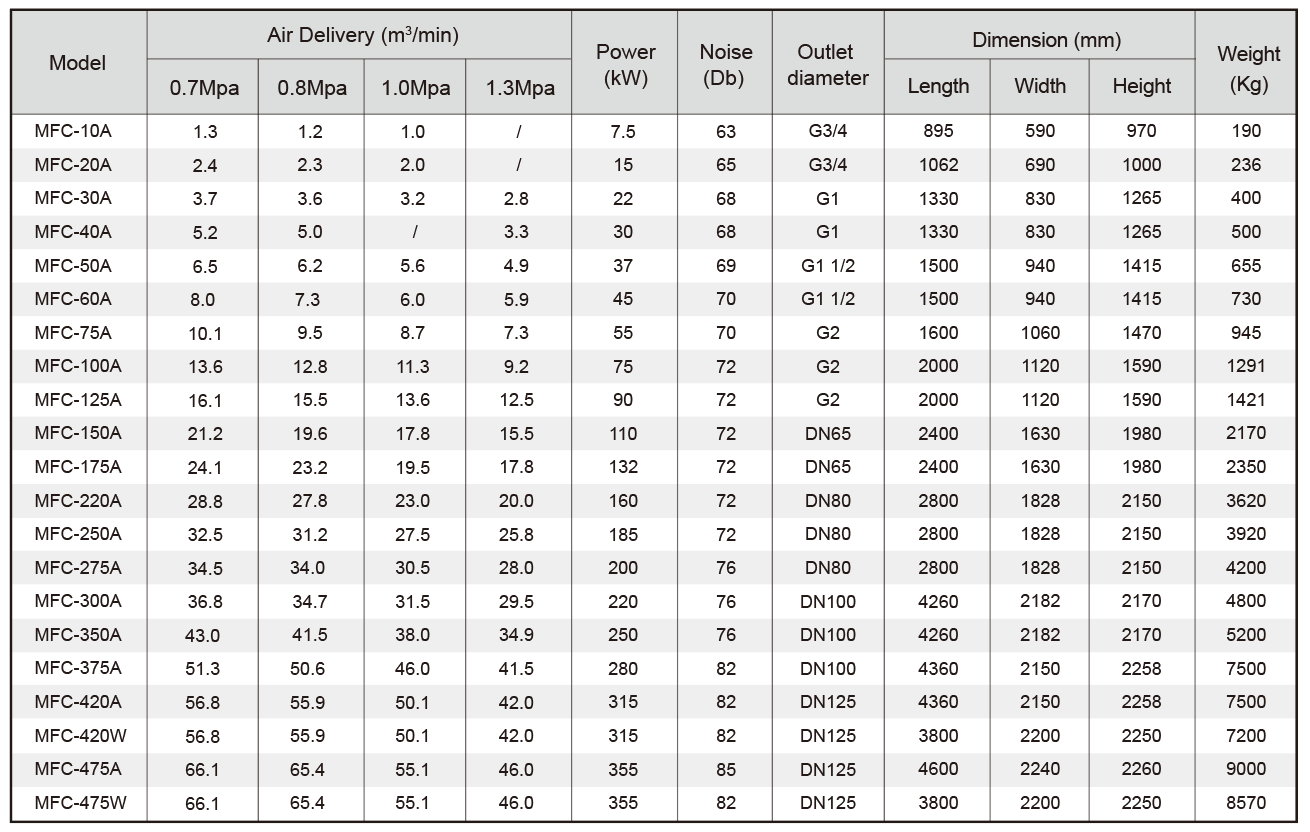

Asynchronous Two-Stage Compression Screw Air Compressor (DD Series)

- Efficient two-stage compression air end The rotor adopts a newly designed patented profile, which ensures that the rotor profile is accuracy, high reliability and availability, low noise, low vibration,Two-stage compression reduces the single-stage compression ratio and reduces bearing loads,Increased air end life.

- High-efficiency asynchronous motor Air-cooled special motor, the input specific power of the whole machine is lower, effectively preventing.Prevent dust and moisture from entering the motor, SKF bearings ensure long-term continuity Trouble-free operation.

- Super Class 1 Energy Efficiency

Specification

Mflow Engineering & Services Sdn Bhd

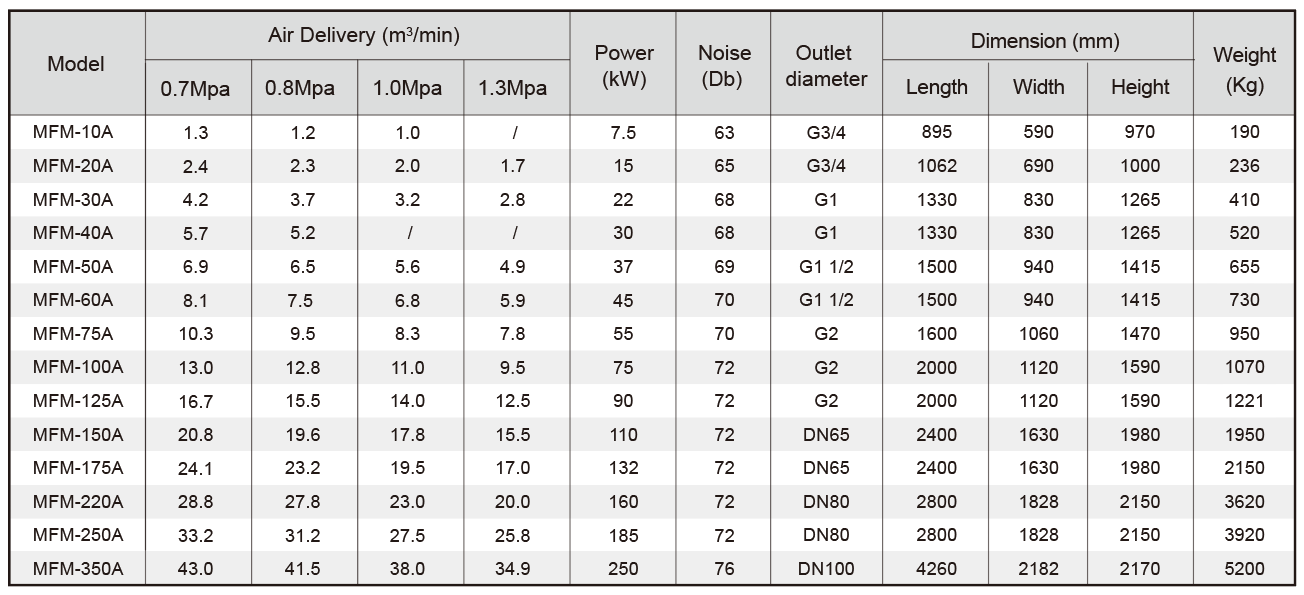

Two-Stage Pm Vsd Screw Air Compressor ( DDM Series )

- Two-stage compressor airend, one-stage energy saving, low vibration and low noise.

- The two-stage compression instead of the single stage compression,the exhaust volume increased by nearly 15%, which can achieve 15% energy saving effect.

- IP65 PM motor with higher efficiency and can be adapted to the poor and dusty working conditions.

- Touchable LED controller, intelligent control, high-efficiency motor protection level IP65.

Specification

Mflow Engineering & Services Sdn Bhd

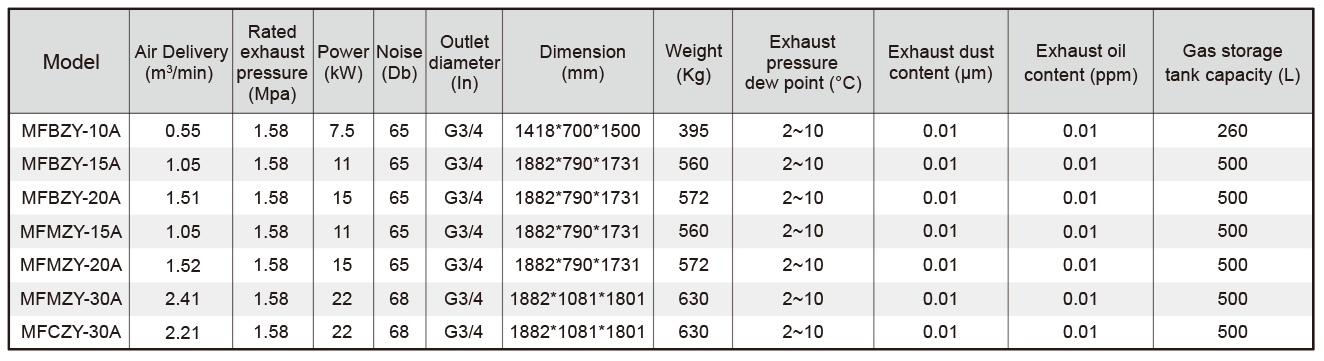

High Pressure Screw Air Compressor For Fiber Laser Cutting Application

- All-in-one design, user-friendly, it can be used when power is ready.

- The original imported airend is used to ensure high efficiency and stability, and smoother cutting.

- Multiple protection devices, multiple shock and noise reduction configurations, low noise.

- High-efficiency refrigerant dryer and 5-level high-efficiency special precision filter, high filtration accuracy, pressure dew point as low as 2~5°C, gas oil content as low as 0.001PPM, particulate matter filtration accuracy up to 0.01um, ensuring pure compression air.

- Constant temperature control. The start and stop of the cooling fan can be set according to the season for the better control on oil

- temperature to avoid emulsification.

- The 500L large air storage tank has buffered air and stable air supply. The precipitation of compressed air in the air storage tank is more conducive to water removal and sewage discharge.

- Centralized drainage after post-treatment is helpful to keep the customer's site clean

Specification

Mflow Engineering & Services Sdn Bhd

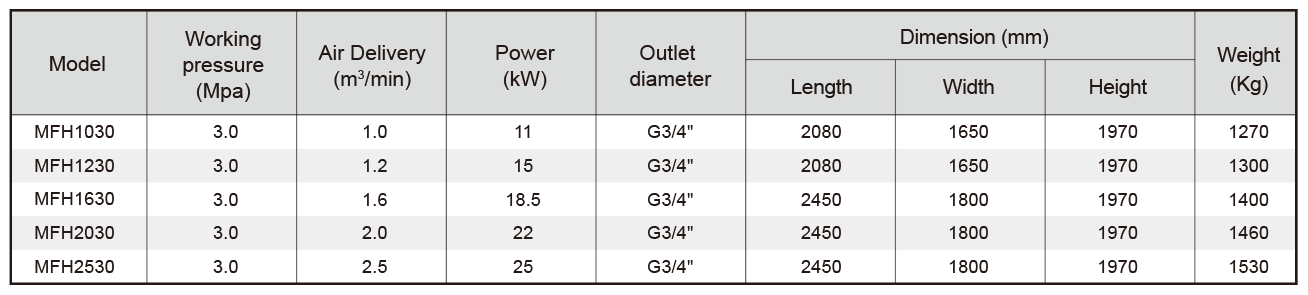

High Pressure Pistion Air Compressor for Fiber Laser Cutting Application

- High compression efficiency. The compression process of piston compressor is in closed status which leads to high compression efficiency.

- Wide pressure range. Medium/high/ultra-high pressure piston compressor can be designed according to different working condition.

- Constant stable exhaust air can be provided when exhaust pressure changes at the same rotation rate