Fixed Speed Screw Air Compressor

- Advanced High Efficiency Air End

- Intelligent Microcomputer Control System

- Unique Heat Removal & Cooling System

- Flexible Coupling Direct Drive

- Safe,Reliable and Efficient Motor

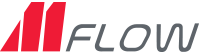

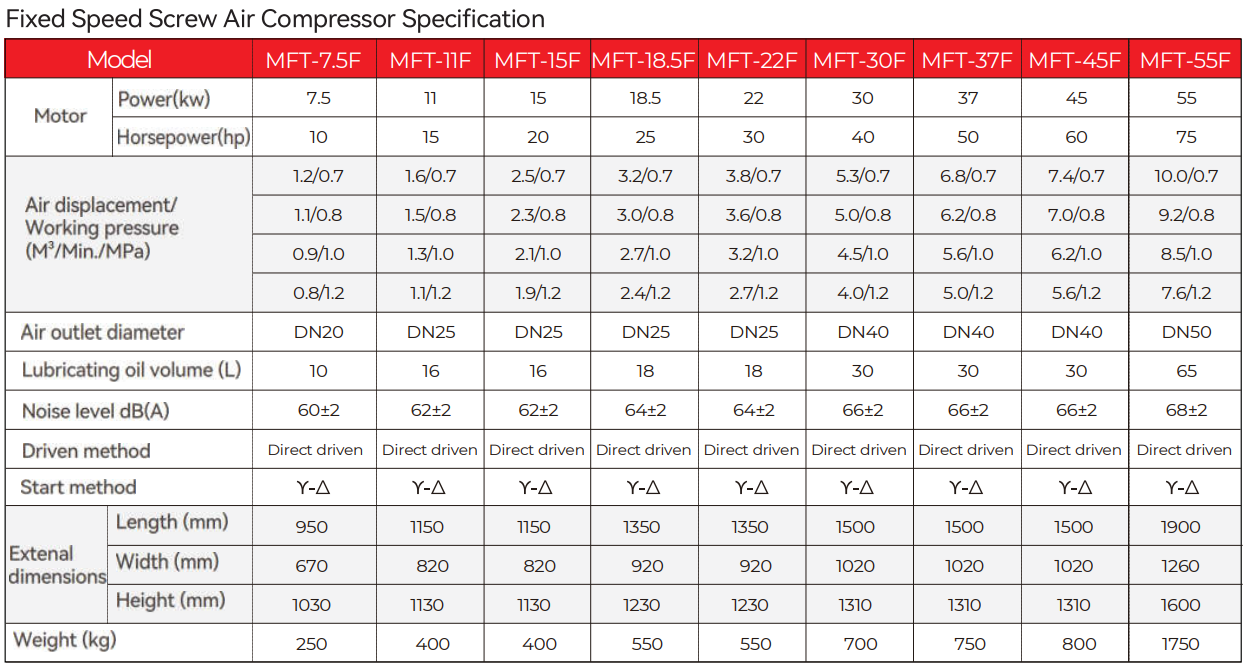

Specification

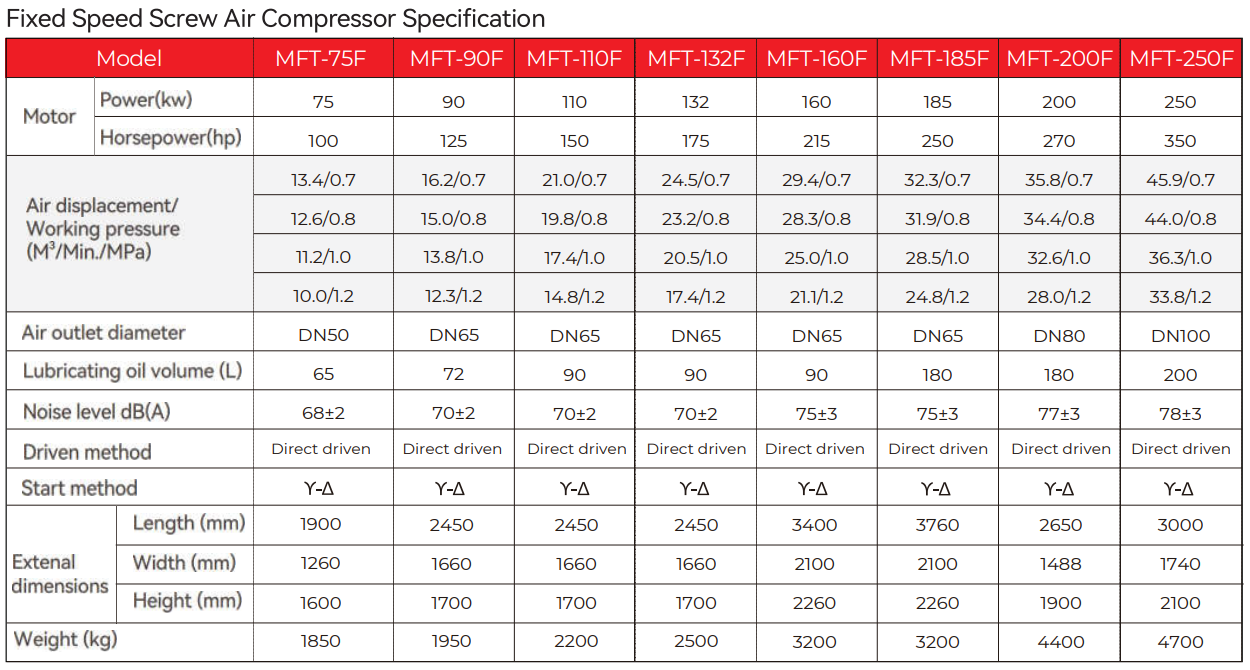

Components

Features

Advanced High Efficiency Air End

Adopts industry-leading screw air end, high efficiency and low rotating speed.With the third generation tooth type of rotor, cutting-edge geometric design-stable, reliable, energy saving and long service life.

Flexible Coupling Direct Driven

Adopts direct connection structure without any loss, transmission efficiency is 100%, maintenance cost is low, disassembleis convenient, greatly save the downtime.Easy maintenance air end maintenance only need to disassemble the air end, motor maintenance only need to disassemble motor, do not affect each other.

lntelligent Microcomputer Control System

Adopts intelligent control system to ensure fully automated intelligent operation, detect exhaust pressure, temperature and other field data, and control the exhaust pressure within the preset pressure range through the intake valve, so as to output stable pressure.

Safe,Reliable and Efficient Motor

Adopts unique low-speed motor, protection grade IP55, insulation grade F, suitable for bad working conditions. High balance precision, high speed running smoothly.

Unique Heat Removal & CooIing System

Adopts advance design, armonica radiator, effectively increase the heat dissipation area, run faster and smoother, and take away the heat of the machine in time. The heat exchange effect of the same area is 30% higher than that of the traditional cooler. Even in the Asia-Pacific region with high temperature and high humidity, the normal operation of the unit can be guaranteed.

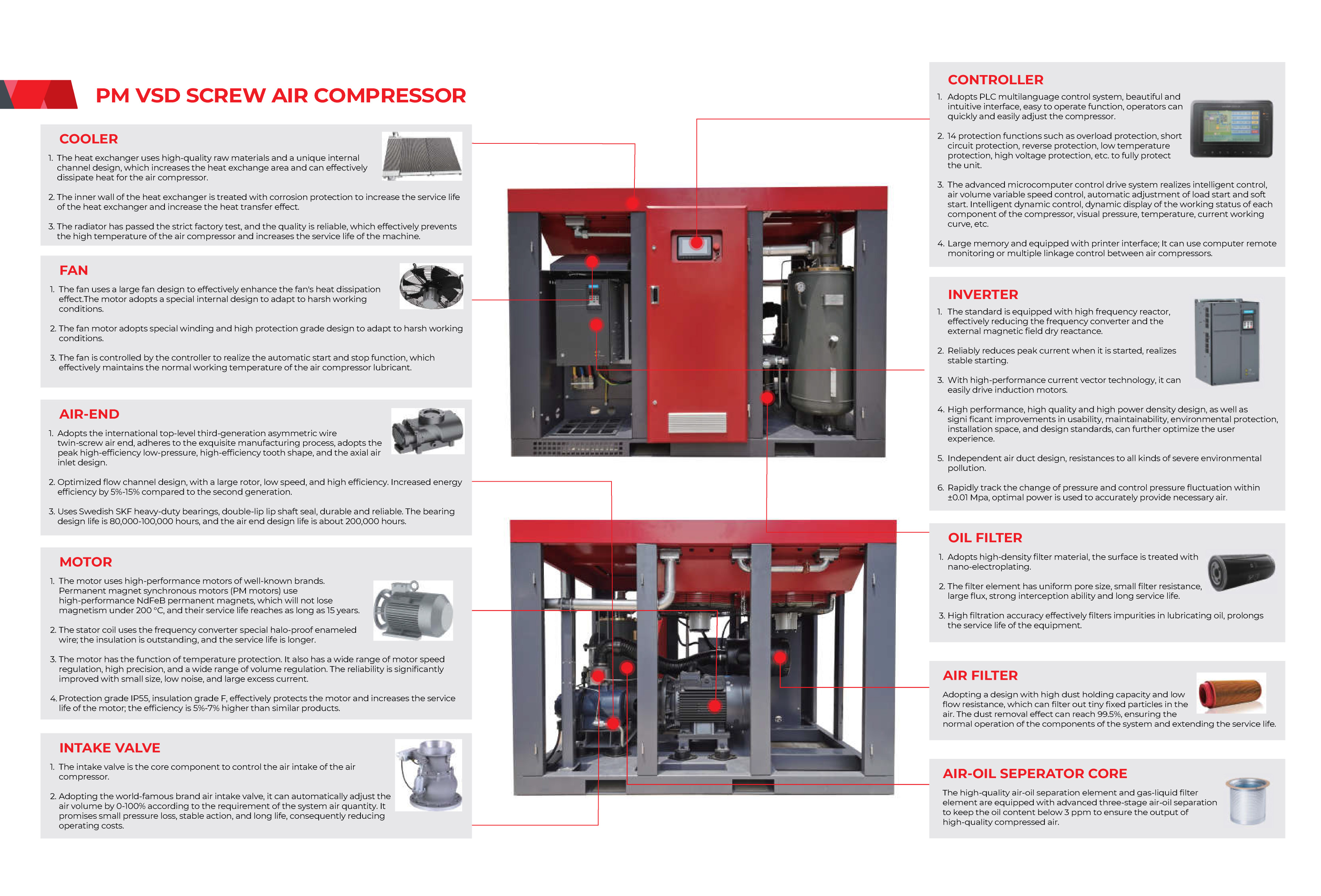

PM VSD Screw Air Compressor

- Intelligent Control System

- The Latest Generation Super Stable Inverter

- Small Start-up Impact

- The Latest Generation High Efficiency Permanent Motor

- Wide Working Frequency Range To Save Energy

- Low Noise

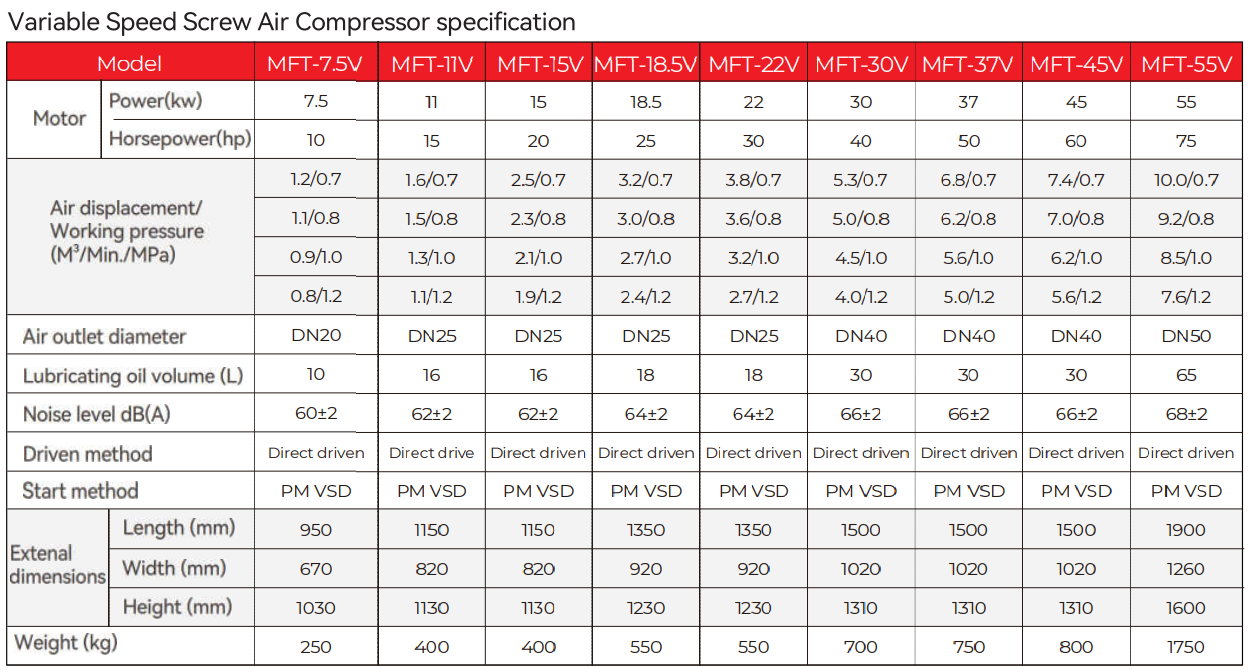

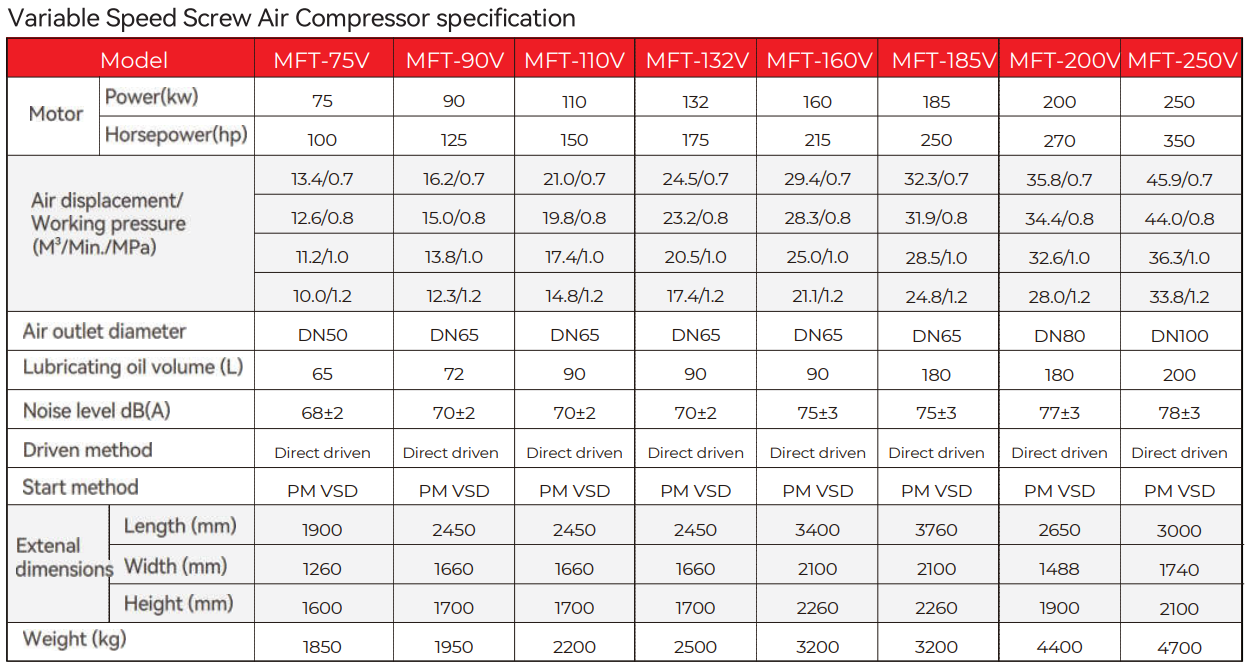

Specification

Components

Features

Intelligent Control System

Direct display of discharge temperature and pressure, operating frequency, current, power, operating state. Real time monitoring of discharge temperature and pressure, current, frequency fluctuations.

The Latest Generation High Efficiency Permanent Motor

Insulation grade F, protective grade IP55, suitable for the bad working conditions.No gearbox design, motor and main rotor through the coupling directly connected, high transmission efficiency. Wide range of speed regulation, high precision, wide range of air flow regulation. The efficiency of the permanent magnet motor is higher 3%-5% than regular motor, efficiency is constant, when the speed drops, still remain the high efficiency

The Latest Generation Super Stable Inverter

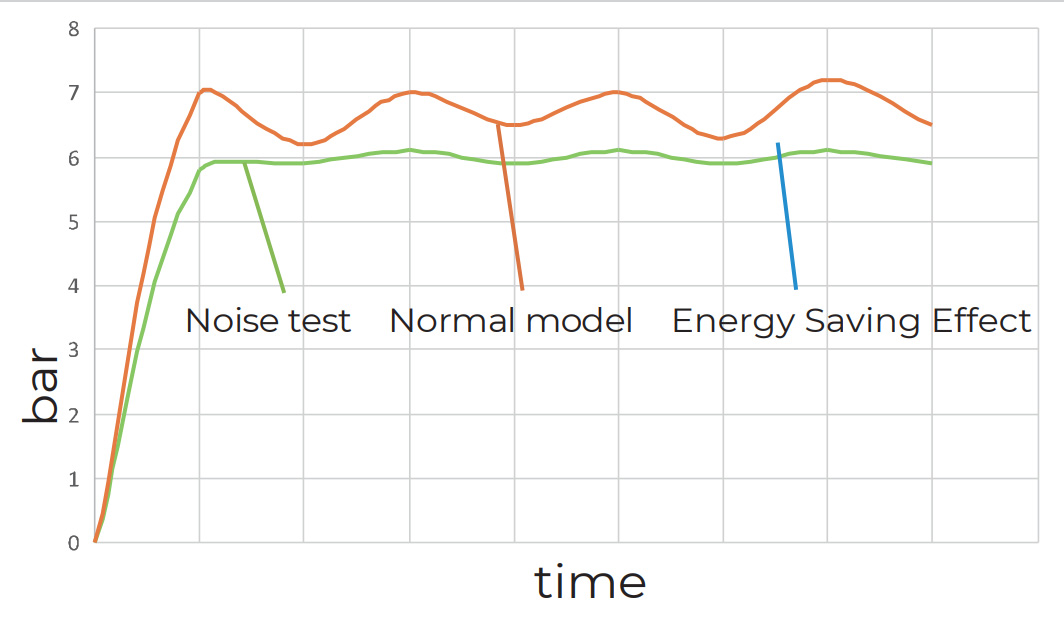

Constant pressure air supply, air suppy pressure is accurate y controlled with in 0.0 1Mpa. Constant temperature air suppy, general constant temperature set at 85⁰C, make the best oil lubrication effect and avoid high temperature to stop.No empty load,reduce energy consumption by 45%, eliminate excess pressure. For each 0.1 mpa increase of air compressor pressure, energy consumption increases by 7%. Vector air supply ,accurate calculation, to ensure that the air compressor production and customers system air demand at all times to maintain the same

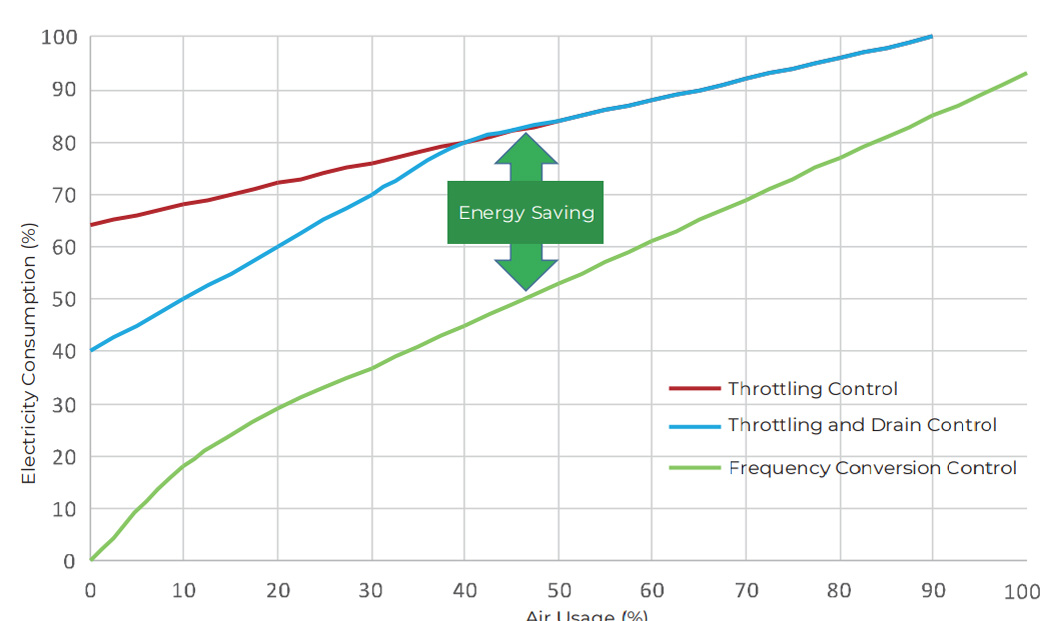

Wide Working Frequency Range To Save Energy

Frequency conversion ranges from 5% to 100%.When the user s gas fluctuation is large, the more obvious energy saving effect and the lower the low-frequency running noise, applicable to any place.

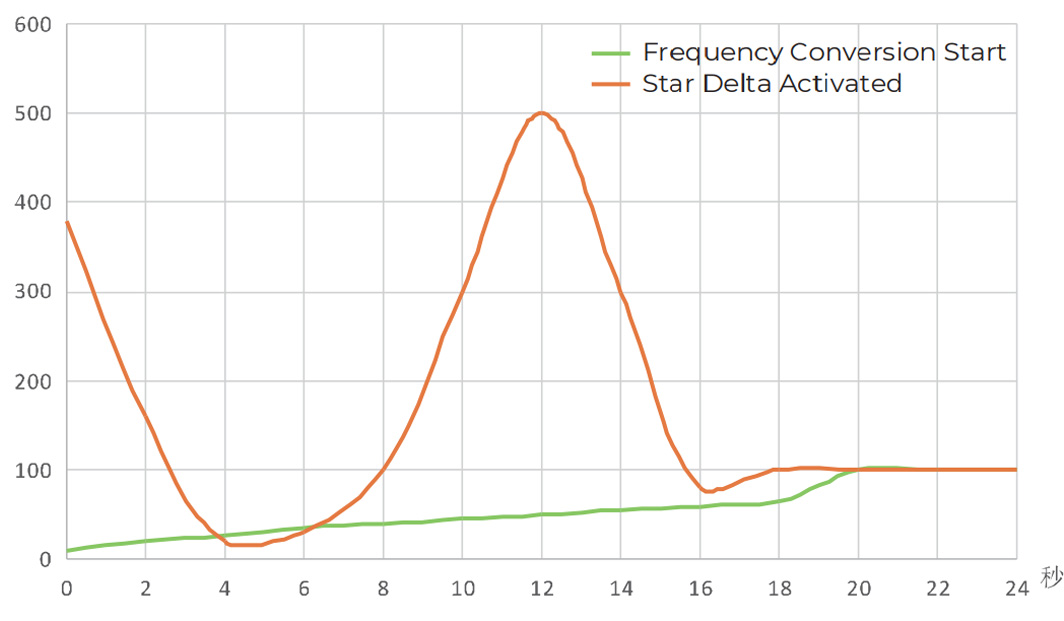

Small Start-up Impact

Use frequency conversion permanent magnet motor, start smooth and soft. When the motor starts, the current does not exceed the rated current, which does not affect the power grid and the mechanical wear of the main engine, greatly reduces the ower failure and prolongs the service life of the main screw machine.

Low Noise

The inverter is a soft start device, the start-up impact very small , noise will be every low when start-up. At the same time, PM VSD compressor running frequency is less than the fixed speed compressor during stable operation, mechanical noise decreases very much.

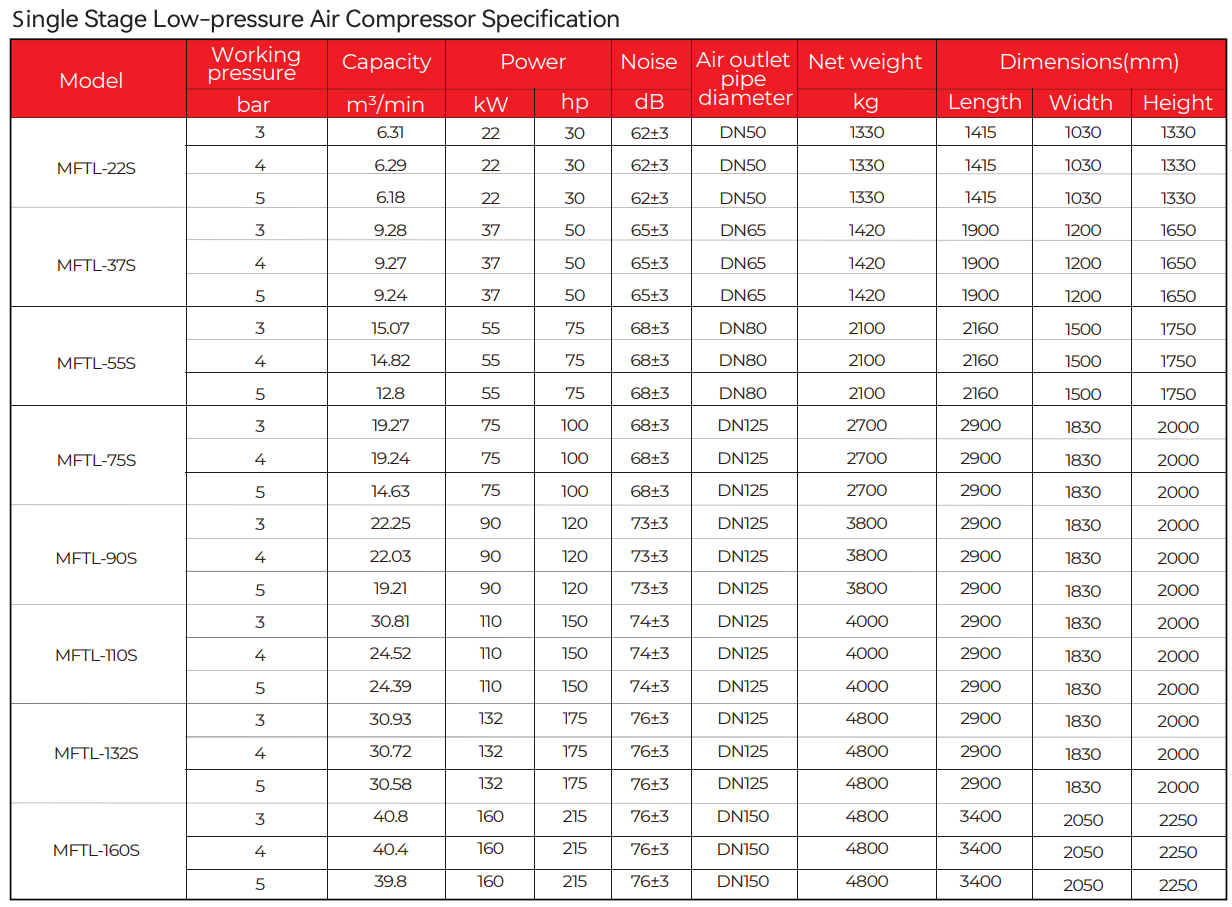

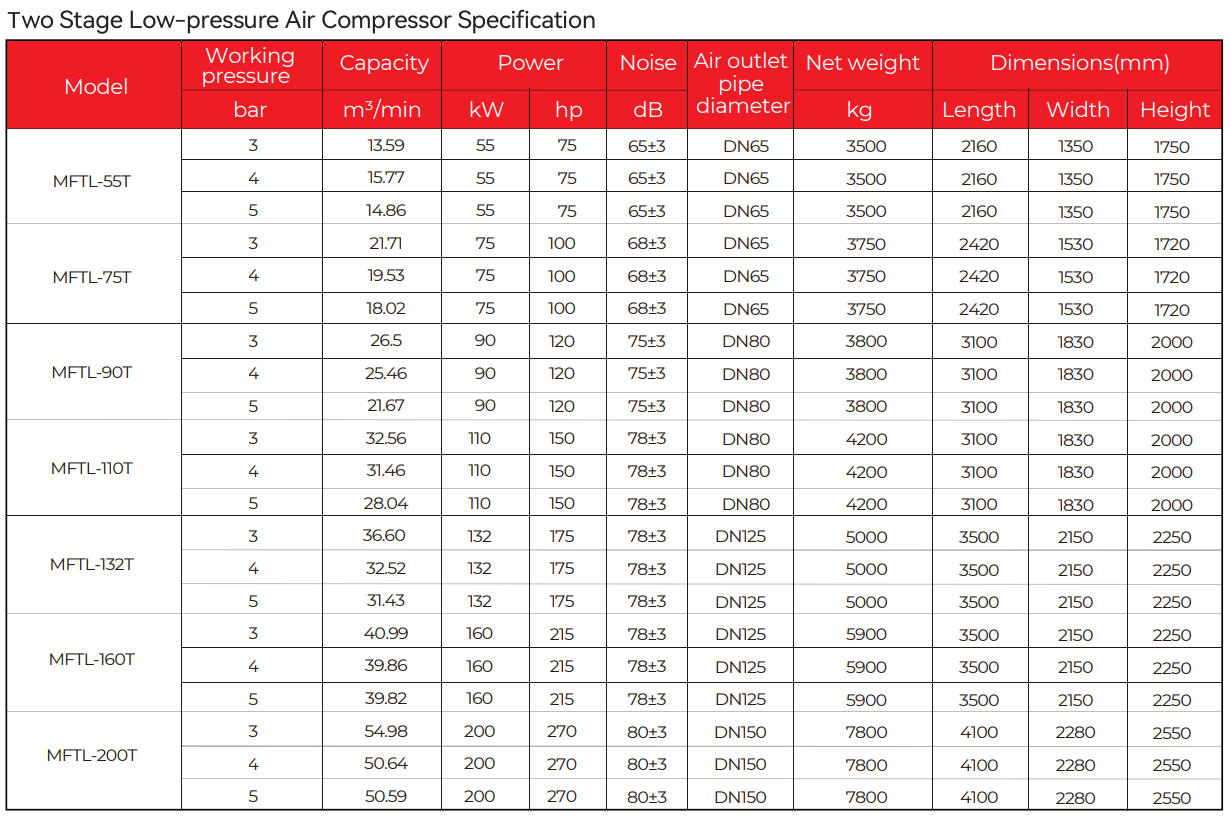

Specification

Description

The host specially developed for low pressure conditions optimizes the screw profile and internal pressure to improve the efficiency of the host. Adopt the design idea of "large rotor, large bearing, low speed" to reduce noise and vibration and increase the life and stability of the host. The tooth surface is processed by a rotor grinder to create a high-precision rotor, which is the first guarantee for the high efficiency and stability of the host. Compared with the atmospheric pressure machine with the same air volume, it can save energy by more than 50%, and the industry application is more energy-efficient. Protect the environment and reduce usage costs.

Low voltage + two-stage design, extremely energy-saving. The unique intermediate coolant jet curtain design reduces the temperature of the air, and the compression process approaches the most energy-saving isothermal compression. lnprindple the two-stage compression saves 5%-8% of energy than the single compression. Two-stage compression, small compression ratio, less leakage, small bearing load, and greatly improved bearing life.